RQQ-TYN

| Reusing existing refrigerant piping minimizes installation time and cost. | |

| Increasing in capacity is possible even with reuse of existing pipe. | |

| Automatic refrigerant charge function ensures correct refrigerant charge even when length of existing pipe is unknown. | |

|

Reusing existing piping for speedy replacement to an advanced energy-saving air conditioning |

|

Time saving

Enables smooth replacement of air conditioning with less effect on operation and user in the building.

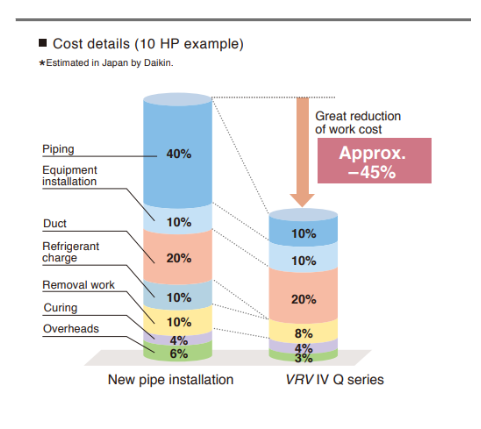

Cost Saving

Work costs for pipe removal, installation and insulation account for almost 80% of the total cost. By the reuse of existing piping, 45% of cost down can be realized compared to installing new pipes. On top of the benefits from reusing pipes, costs of charging refrigerant to clean the pipes are also saved.

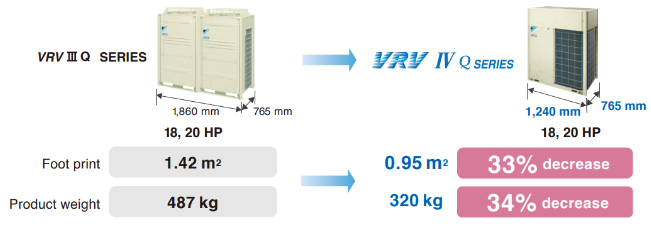

Space saving

As a leading global innovator, Daikin advanced from the conventional 2 module combination to a single module for 18 and 20 HP models. This allows the installation area to reduce by 33% as compared to the previous models.

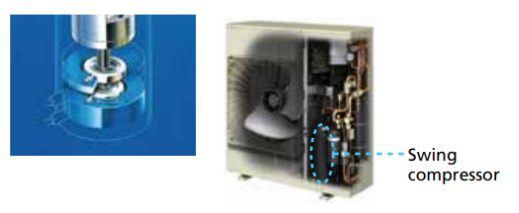

Swing compressor

Daikin swing compressor has integrated the rotor with the blade, completely solving the refrigerant leakage and the wear problem caused by the mechanical friction between the rotor and the blade, which enhances the compressor efficiency and makes the compressor more quiet and durable.

New technology that enables use of existing piping

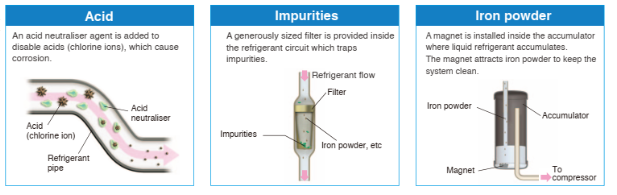

A new method collects contamination from existing piping, eliminating compressors and electric valves malfunction

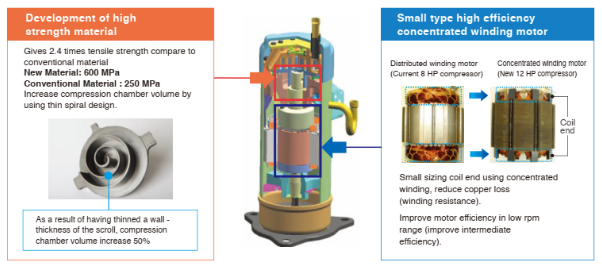

Large capacity all DC inverter compressor in compact casing

Large capacity all DC inverter compressor using high tension strength material, realize 12 HP compressor using 8 HP casing.